INDUSTRY EXPERTISE

Maximize Profits and Increase Efficiency with Specialized Laser Systems

reACTIV Laser Systems collaborates with a diverse range of industries to enhance operational efficiency and add significant value. By integrating advanced laser technology into various processes, our systems enable precise cutting, engraving, and marking, leading to improved accuracy and reduced waste. This adaptability allows businesses in manufacturing, healthcare, automotive, and more to streamline workflows, minimize downtime, and optimize resource utilization.

Through tailored solutions, reACTIV empowers organizations to achieve their goals more effectively, fostering innovation while maintaining high-quality standards.

Look below for examples.

reACTIV LASER TECHNOLOGY WITHIN THE

Medical Device Industry

WITH OVER 25 YEARS OF EXPERIENCE IN THE MEDICAL INDUSTRY, SEE HOW WE MAXIMIZE PROFITS:

Trauma Implantables for broken bones

Medical Devices and Tools

Product Identification and Traceability

reACTIV LASER TECHNOLOGY WITHIN THE

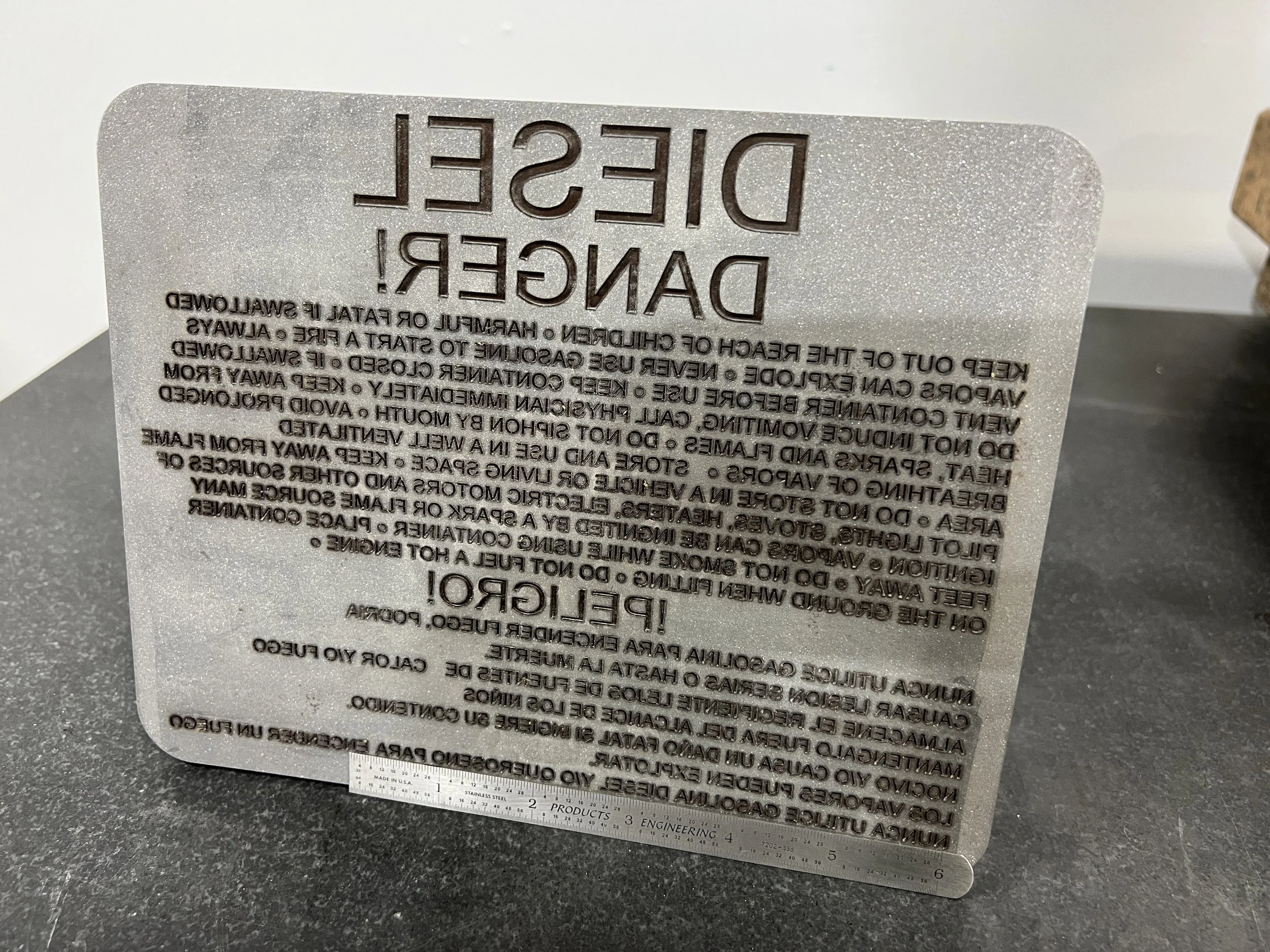

Mold Making and Tool and Die Industry

At reACTIV Laser Systems, we play a critical role in supporting the mold making and tool and die industry by delivering precise, durable, and fully customized laser solutions.

Our advanced laser marking, engraving, and cutting technologies help our clients achieve exceptional accuracy and repeatability when producing and identifying high-performance tools and molds. Whether we’re engraving detailed part numbers, creating intricate designs on hardened tool surfaces, or cutting components to exact tolerances, our systems are built to meet the demanding standards of industrial production.

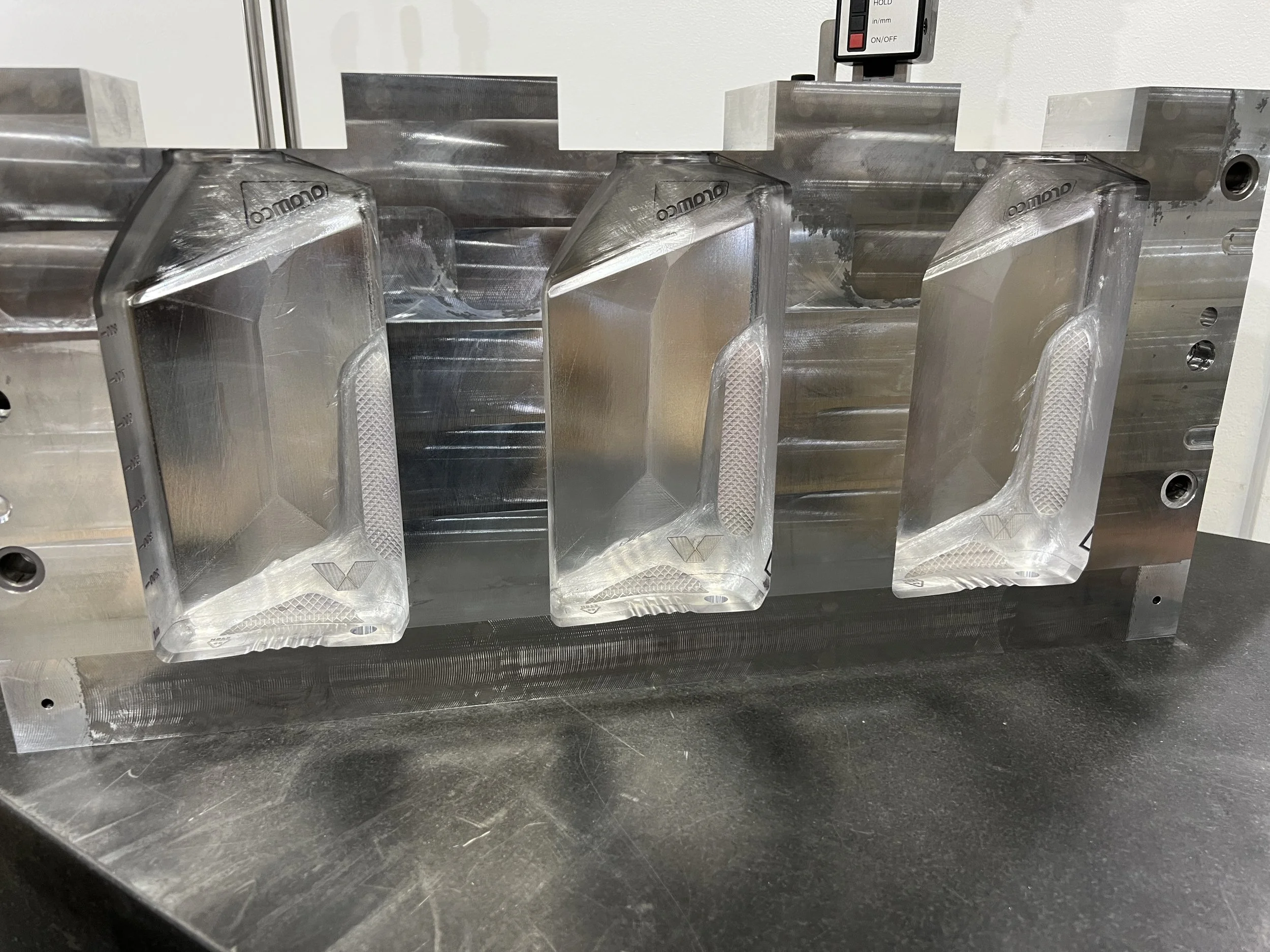

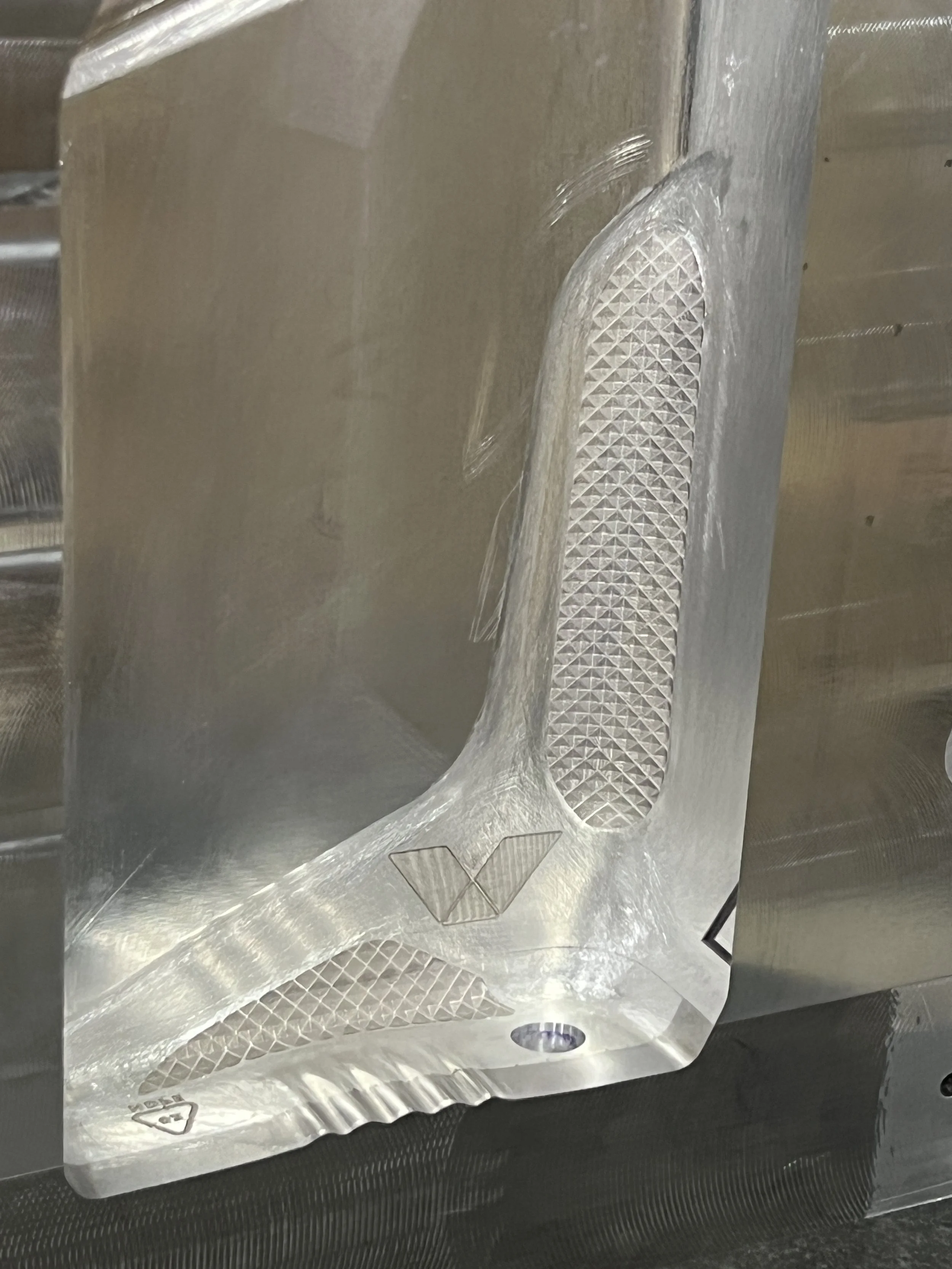

Laser texturing of a gun stock mold

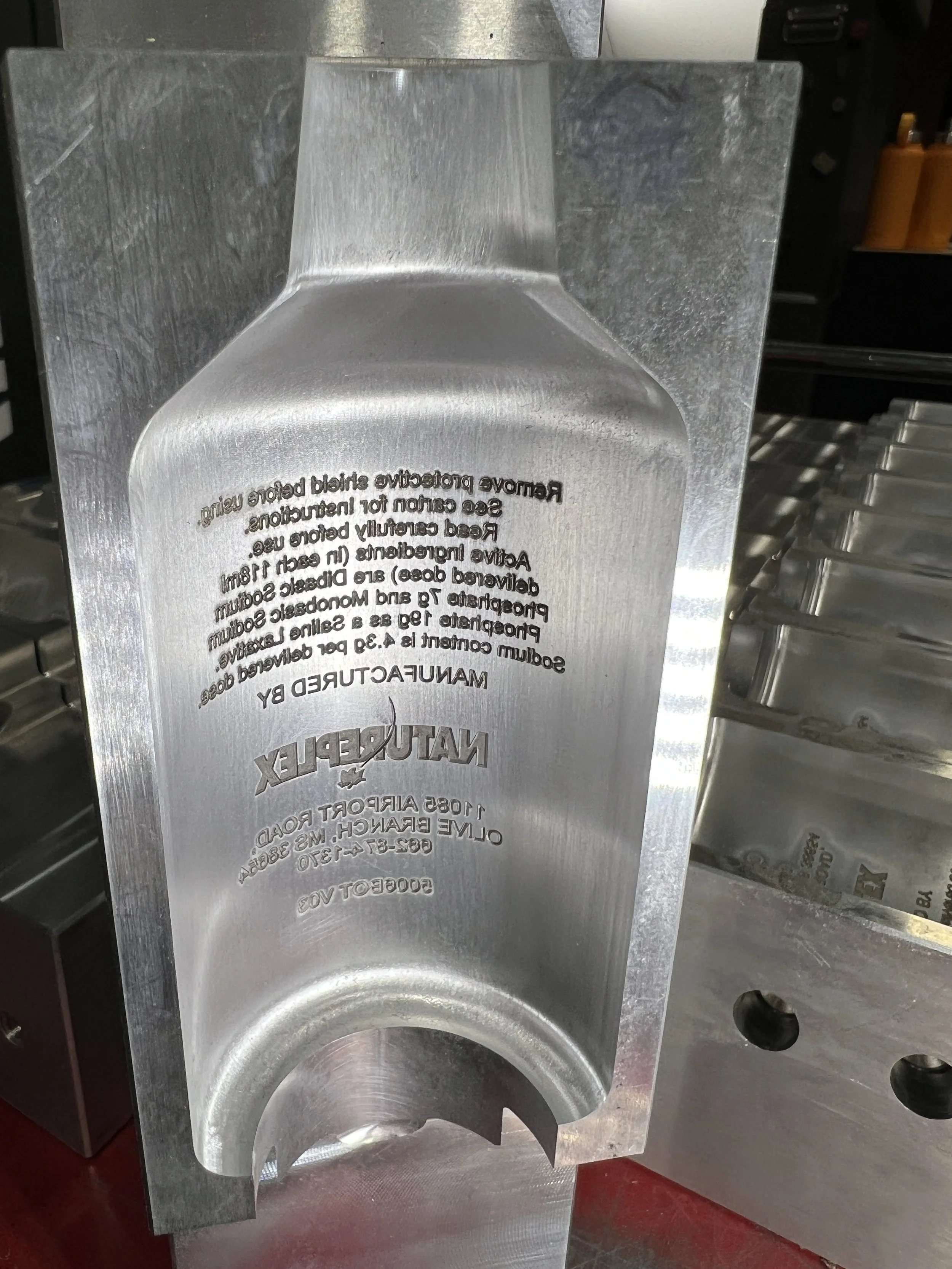

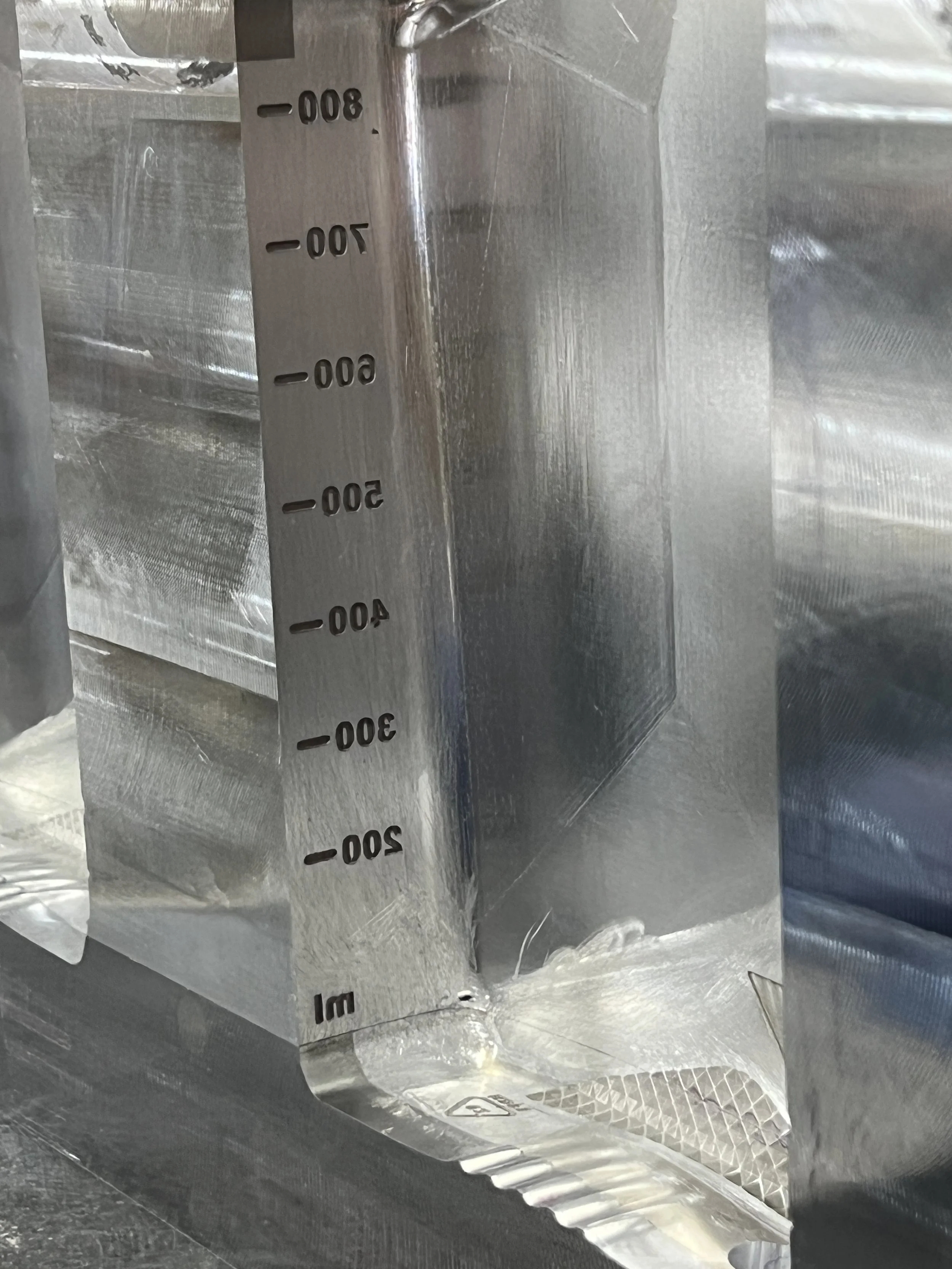

2D Laser engraving of a blow mold insert

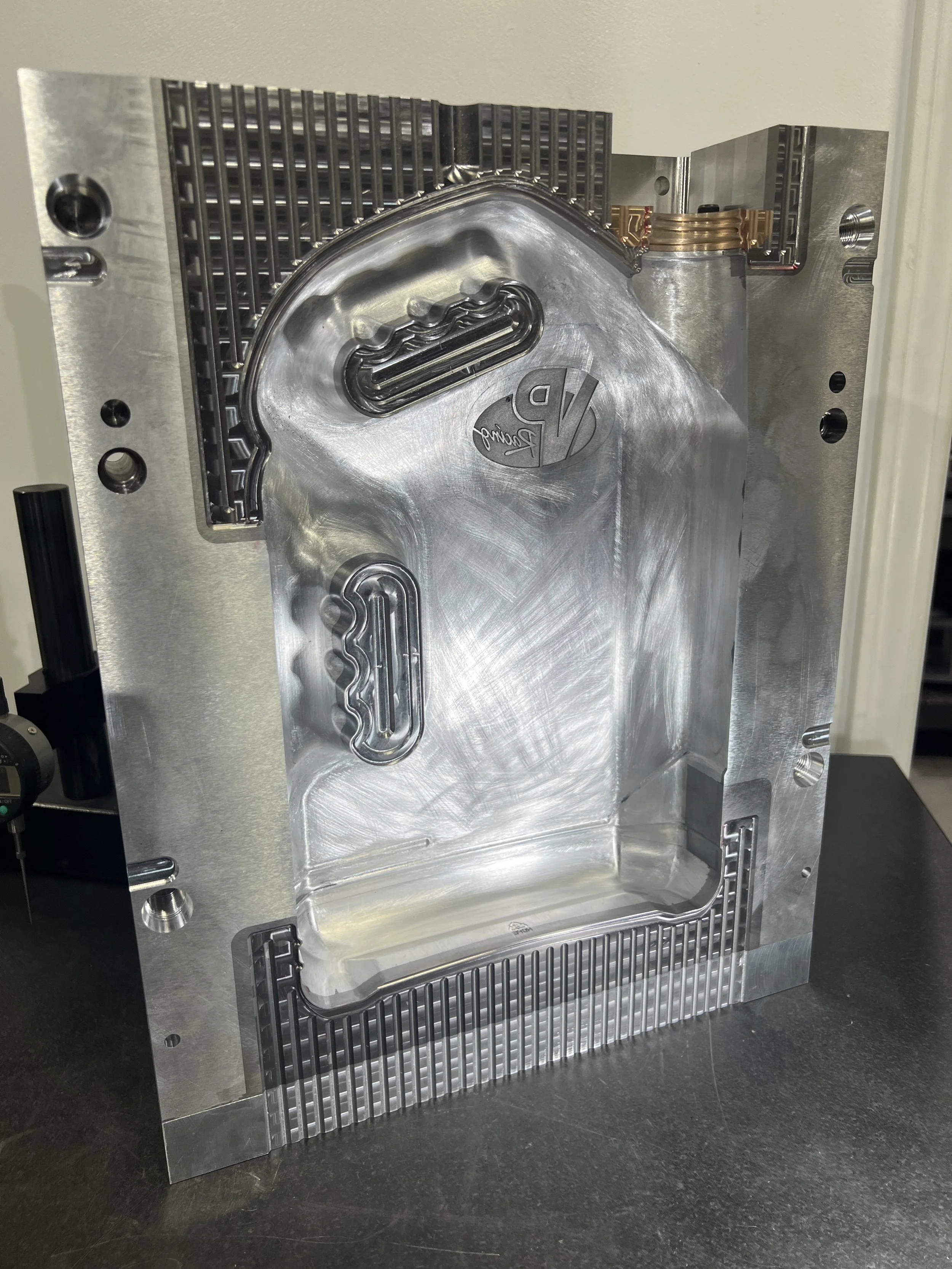

3D Mold engraving

3D Mold engraving

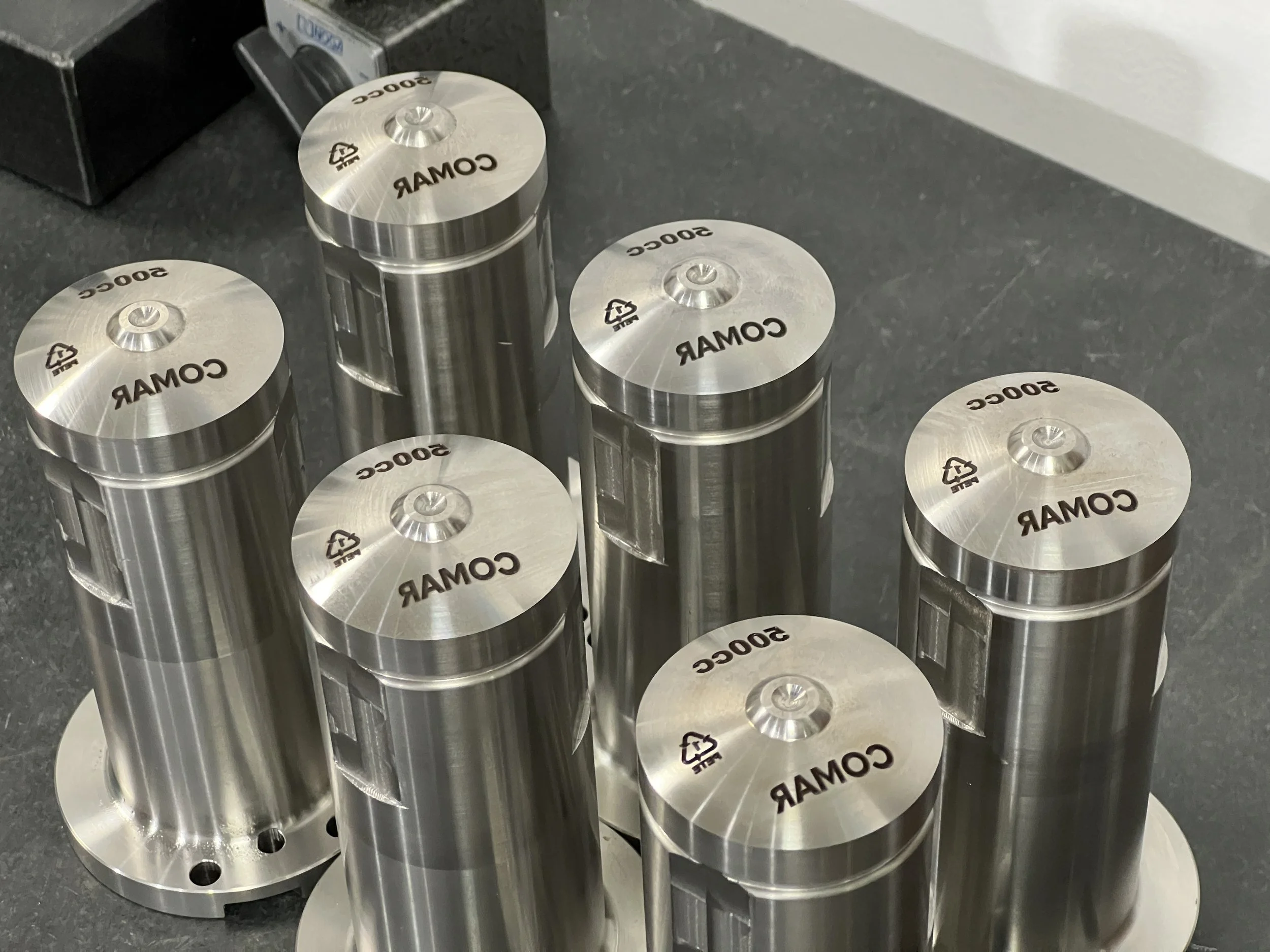

3 Cavity extrusion gang mold

3D Laser engraving of customer brand, 3D texturing of geometric grid pattern

3D Laser engraving of customer brand, 3D texturing of geometric grid pattern

2D Laser engraving of side graduations for bottle fill level

3D Texturing for geometric grid pattern

2 Cavity gang mold

3D Laser engraving of rib feature for grip and bottle rigidity

3D Laser engraving of customer logo

Laser engraving of mold base for plastic bottle

Laser engraving of mold base for plastic bottle

3D Laser engraving of decorative filigree in bottle mold

Whole bottle form from above

reACTIV LASER TECHNOLOGY WITHIN THE

Private Minting Industry

WITH OVER 25 YEARS OF EXPERIENCE IN THE MINTING INDUSTRY, SEE HOW WE MAXIMIZE PROFITS:

2D Engraving

3D Engraving

Die Frosting

3D Die Frosting

Micro Engraving

Security Features

WHY WORK WITH

REACTIV LASER SYSTEMS?

100%

USA designed, built and supported.

25

years experience in the laser industry.

+25%

increased efficiency in engraving cycle times compared to competitors.

6-10x

faster die frosting speeds than our average competitor.

Ready To Get Started?

Let's get in touch to get a jump start on your project.