BLOG

Offering Contract Laser Marking, Engraving, Welding and Cleaning

The laser services team at reACTIV focuses on quick turn around and high quality customer service by building relationships and education on customer products and needs.

New Product Release: Standalone Compact Laser System

With expanding customer needs through out the market, reACTIV Laser Systems is bringing another advancement to their product line with the Standalone Compact Laser System.

We are Transforming How We Think about Our Systems

We don’t think you should have to name every feature that you need to find something that works for you. That’s why we are creating laser systems with all of the greatest standard features ready to go.

Post-MT Series Wrap-Up – Welcome & What’s Ahead from reACTIV

We’re back from the MT Series event in Dallas, where we had the opportunity to connect with innovators, manufacturers, and future-focused thinkers from across the industry.

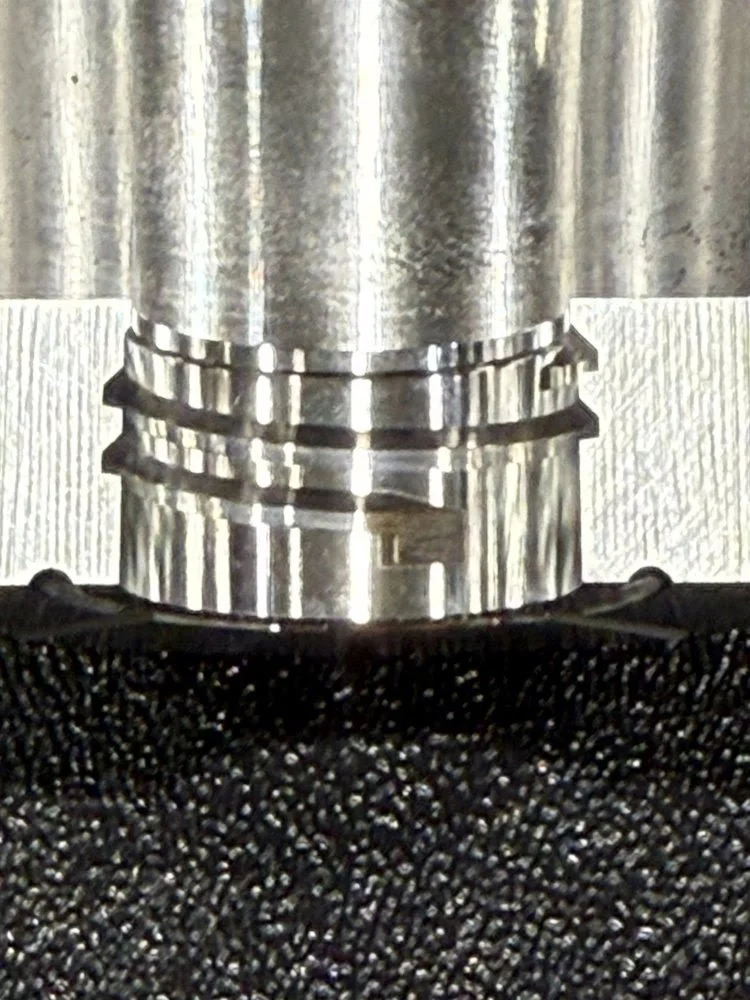

3D Laser Machining to Replace EDM in Manufacturing

3D laser machining of thread features for locking mechanisms in plastic bottle molds is a prime example of technological advancement and process improvement within conventional mold manufacturing.

Come See Us in Dallas at the Manufacturing Technology Series SOUTHWEST Event

The MT Series SOUTHWEST tradeshow is a dynamic three-day event designed to showcase the future of manufacturing through technology, thought leadership, education, and networking. Key features include…

The Importance of Long Term Supportability and Partnership

A core value and commitment reACTIV Laser makes to its customers is the long-term supportability of the products we engineer and build.

Why we Repair (and Upgrade) Laser Systems from Any Manufacturer

This customer purchased their laser system from a different US based manufacturer approximately 14 years ago.

Benefits of Plastic Marking

reACTIV Laser Systems offers USP (ultra short pulse) and Nanosecond laser solutions in IR, (SHG) Second Harmonic Generation and (THG) Third Harmonic Generation.

Laser Engraving for Automotive Traceability

reACTIV wants to develop solutions built around YOU, rather than compromise the process and limit your abilities.

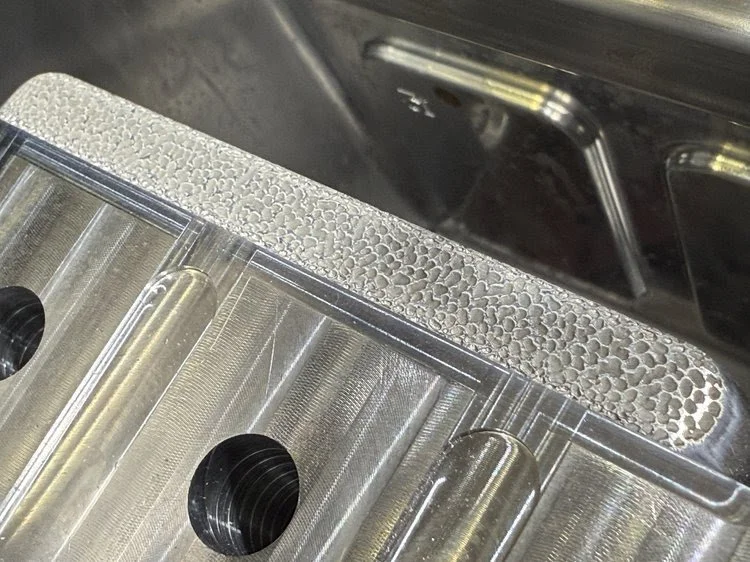

Solution of the Month: Laser Texturing

reACTIV Laser Systems builds multi-axis 3D engraving systems for manufacturing.

Solution of the Month: 3D Engraving / Micro Machining

Production manufacturing of injection mold components is a highly technical process utilizing many traditional manufacturing techniques such as Milling, Turning, Grinding and EDM processes.

Solution of the Month: Our Latest Machine

This custom laser system was built to order to work with large injection and blow mold components.

The Importance of Dedicated Technical Support with Laser Systems

reACTIV Laser Systems is serious about technical support. We won’t make you wait - we know that having your system running at 100% is of utmost importance.

Solution of the Month: Product Identification using Laser Marking and Engraving

Product identification is not only simple branding with company logos for products, but also includes important and complex product tracking and traceability.

Solution of the Month: Custom Designed and Built Laser System

Designed, manufactured, customer tested and delivered in approximately 14 weeks.

Solution of the Month: Low Cost, High Value Laser System

Integration of a 30 watt fiber laser system onto an existing mill platform for customer to utilize with large heavy molds and dies.

What is 3D Texturing and Engraving? Applications, Benefits & Advanced Techniques

This technique is used for various applications like adding decorative patterns to products, enhancing surface functionality by improving…