Solution of the Month: Laser Texturing

reACTIV Laser Systems builds multi-axis 3D engraving systems for manufacturing.

By utilizing advanced scanning technologies, we are able to reproduce natural and geometric textures with precision. For mold manufacturing, these scanned textures are mapped onto the digital mold design and then exported to the laser system for high-quality, accurate 3D laser engraving. By leveraging 3D engraving, reACTIV Laser Systems can reduce manufacturing costs and shorten delivery times compared to traditional processes.

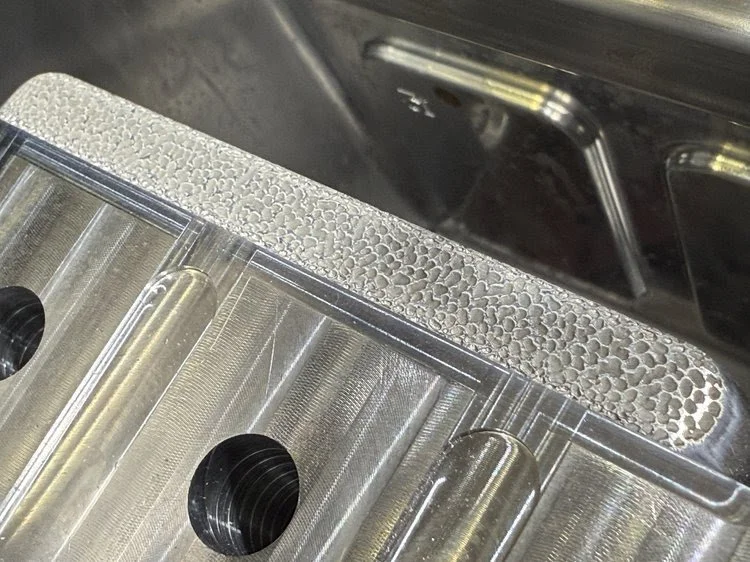

The above picture shows an example of a function texture in a grip feature of a consumer bottle.