Solution of the Month: 3D Engraving / Micro Machining

1/10 THE SIZE OF TRADITIONAL TECHNOLOGIES

Production manufacturing of injection mold components is a highly technical process utilizing many traditional manufacturing techniques such as Milling, Turning, Grinding and EDM processes.

With the utilization of reACTIV Laser Technology we are able to create features and structures 1/10 the size of those traditional technologies. Laser processing is not only highly accurate with a much greater resolution, but on average 4-5 times faster than traditional processing.

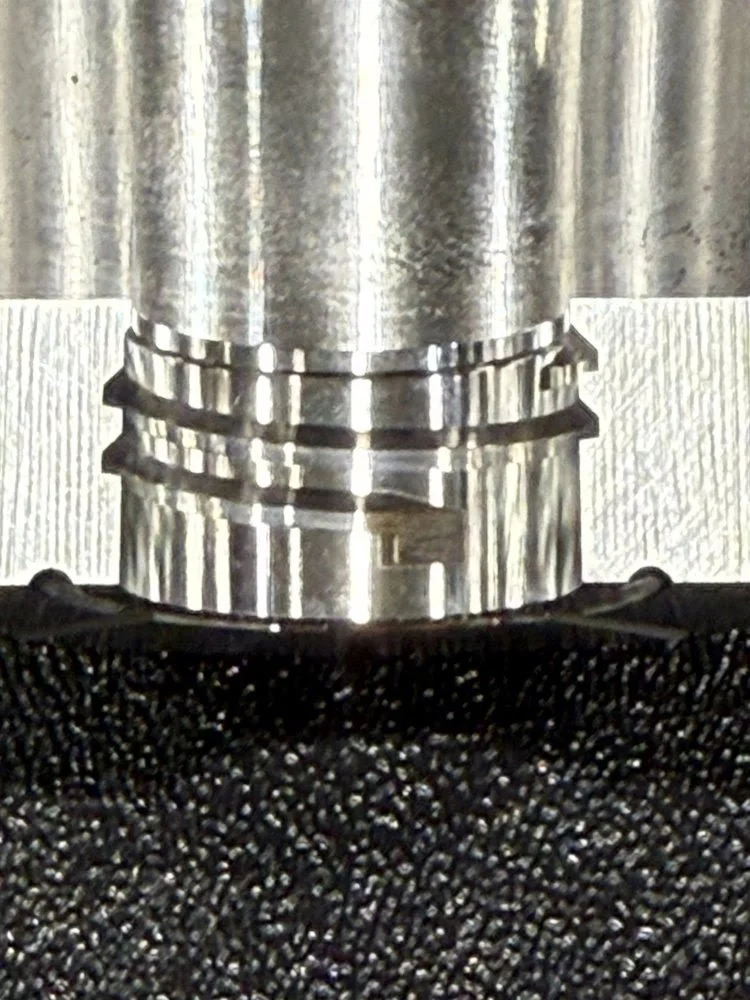

Thread Stop

This example of a thread stop for a bottle cap closure thread shows how traditional thread grinding is used to efficiently create the thread profile.

At the end of the thread the "ramp like" thread stop feature is added with laser. The combination of traditional grinding and laser 3D Engraving / Micromachining saved this customer hour of manufacturing time and hundreds of dollars per part.